-

1986

By introducing advanced computer-controlled technology from Italy, we have broken through the constraints of traditional low-end manufacturing techniques. This innovation has led to the successful development of filament-wound FRP (Fiberglass Reinforced Plastics) storage tanks and pipelines. Not only has this achievement significantly enhanced production efficiency and product quality, but it also lays a solid foundation for the diversified applications and high-quality sustainable development of FRP materials in the future.

-

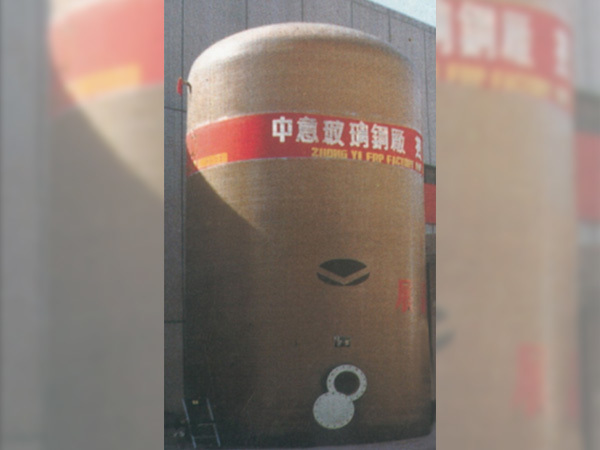

1986

The advent of filament-wound FRP storage tanks, emerging from JIZHOU ZHONGYI collaboration, marks a milestone in cementing composite materials' pivotal role in industrial manufacturing.

-

1987

The FRP filament-wound absorption towers developed exclusively for Wuhan Iron & Steel Group (WISCO) have successfully replaced imported equivalents, marking China's pioneering breakthrough in indigenous manufacturing of industrial tower systems.

-

1988

Building upon the introduction of on-site filament winding technology for large-scale vessels from Italy, we delivered NF-standard compliant complete equipment systems for French SB Company within the same year. These systems were successfully commissioned at China-Arab Fertilizer Co., Ltd.'s ammonium phosphate project.

-

1991

Application of on-site filament-wound FRP (Fiberglass Reinforced Plastic) large-scale vessels in the chemical industry field

-

1992

Introduced filament-wound fiberglass reinforced plastic (FRP) mortar pipe production line from Italy and successfully promoting the application of FRP mortar pipes in the municipal water supply and drainage sector.

-

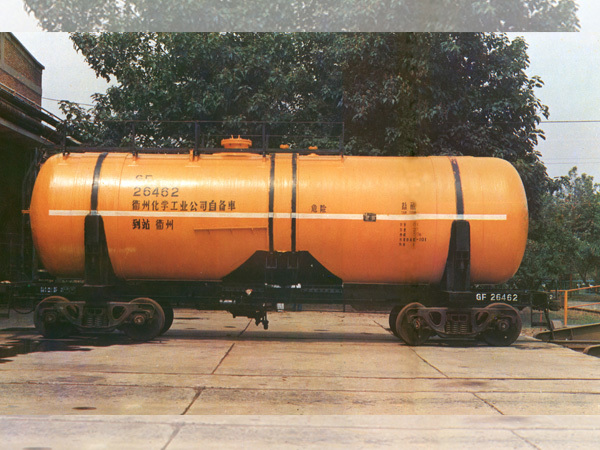

1993

Cooperated with Xi'an Vehicle Factory to jointly develop a special fiberglass reinforced plastic (FRP) tank car for railway transportation, which has obtained a national patent.

-

1994

The large-diameter and long-distance fiberglass reinforced plastic (FRP) mortar pipelines have been successfully operated in the swamp areas of Daqing, marking the beginning of the promotion and application of FRP mprtar pipelines in China.

-

1994

Use finite element programs for product design.

-

1997

Passed the ISO9001 quality management system certification and obtained quality certification certificates from six countries, namely Switzerland, France, the United States, the Netherlands, Germany and China.

-

1998

Obtained the quality certification from the Norwegian Classification Society for fiberglass reinforced plastic (FRP) pipes.

-

2004

Restructured into JIZHOU ZHONGYI FRP CO., LTD.

-

2006

Passed the certifications of the ISO14001:2004 Environmental Management System and the OHSAS18001:1999 Occupational Health and Safety Management System.

-

2006

Integrated fiberglass reinforced plastic flue gas duct between chimney and cooling tower system designed and manufactured by JIZHOU ZHONGYI has been successfully applied in the field of flue gas desulfurization in power plants.

-

2007

The ribbon-cutting ceremony for the new plant area was grandly held at Xinghua Plant.

-

2007

The FRP (Fiberglass Reinforced Plastic) flue gas duct, independently designed, manufactured, and installed by JIZHOU ZHONGYI, has been completed and successfully put into operation at the Beijing Sanhe Power Plant.

-

2008

Awarded as a “Hebei Province Integrity Enterprise”

-

2008

The ultra-large FRP pipelines resistant to seawater corrosion and the mobile winding equipment were appraised and certified by the Science and Technology Development Center of the Ministry of Education.

-

2008

The DN1400 FRPM (Fiberglass Reinforced Plastic Mortar) pipeline for the Beijing Olympic Infrastructure Project—the Yinwen Ruchao Project in Shunyi, Beijing—was successfully delivered and completed.

-

2008

The FRP pipelines produced for Israel's IDE Technologies, intended for the Circular Economy Project of the Tianjin Guotou Jinneng Power Generation Beijiang Power Plant, have been completed.

-

2008

The large FRP flue gas duct for the 'Integrated fiberglass reinforced plastic flue gas duct between chimney and cooling tower system' exhaust cooling tower, designed by Beijing Guodian North China Power Engineering Co., Ltd. and manufactured and installed by JIHZOU ZHONGYI, has been successfully put into operation at the Jinzhou Power Plant.

-

2009

Certified as a High-Tech Enterprise by the Provincial Department of Science and Technology.

-

2009

Introduced Canada's ZCL double-walled tank production technology, becoming the first company in China to promote FRP FF double-walled petroleum storage tanks in petroleum and petrochemical gas stations.

-

2009

Our self-developed PP-lined FRP reinforced storage tank for coal chemical desulfurization liquid has resolved the long-standing corrosion resistance issues faced by coal chemical enterprises using metal-lined tanks. This technology was granted a national invention patent.

-

2010

Obtained licenses for pressure vessel design/manufacturing and pressure pipeline component production.

-

2011

Awarded the 'AAAA-Level Standardization Excellence Enterprise' title by the Provincial Technical Supervision Bureau.

-

2012

Fifty technicians from JIZHOU ZHONGYI obtained FRP filament winding and hand layup vocational qualification certificates issued by the China Building Materials Federation.

-

2014

JIZHOU ZHONGYI participated in the Conference on Interaction and Confidence-Building Measures in Asia (CICA Summit) as a representative of Chinese enterprises.

-

2015

JIZHOU ZHONGYI received the Hebei Provincial Government Quality Award."

-

2016

Developed and installed China's first FRP-based micro-wind power generation system.

-

2018

Innovated large-scale square tanks without internal bracing, successfully solving corrosion resistance challenges in new energy nickel and cobalt metal extraction equipment.

-

2020

Adopted advanced technology from Singapore's Dynaglass, introducing the Vap-O-Loc high-performance floating roof to China, fundamentally addressing VOC emissions from gaps in domestic oil storage tank floating roofs.

-

2021

Acquired special equipment production licenses for PE gas pipelines

-

2021

Acquired sanitary approval certificates for PE pipes.

-

2022

Aligned with China's Belt and Road Initiative, the company adhered to a global expansion strategy, designing and manufacturing a 7.5-meter-diameter composite flue gas system for Turkey's Hunutlu Power Plant. In 2023, it withstood a local 7.8-magnitude earthquake, demonstrating the robust quality of 'Made in China'.

-

2023

Designed and constructed a complete bromine stripping and absorption system for Laos' Asia Industrial Park 10,000-ton bromine project, achieving the 'Laos Miracle' characterized by a short construction cycle, large single-unit capacity, and high bromine extraction rate.

-

2024

Recognized as a National-Level Specialized, Sophisticated, Innovative, and Emerging 'Little Giant' Enterprise by the Ministry of Industry and Information Technology.