Products

Contact Us

Telephone:

086 318-8613433 086 318-8638136

Mobile:

+86 13931832669 +86 13932879971

Address:

No.955 Xinghua South Street, Jizhou District, Hengshui City, Hebei Province,China

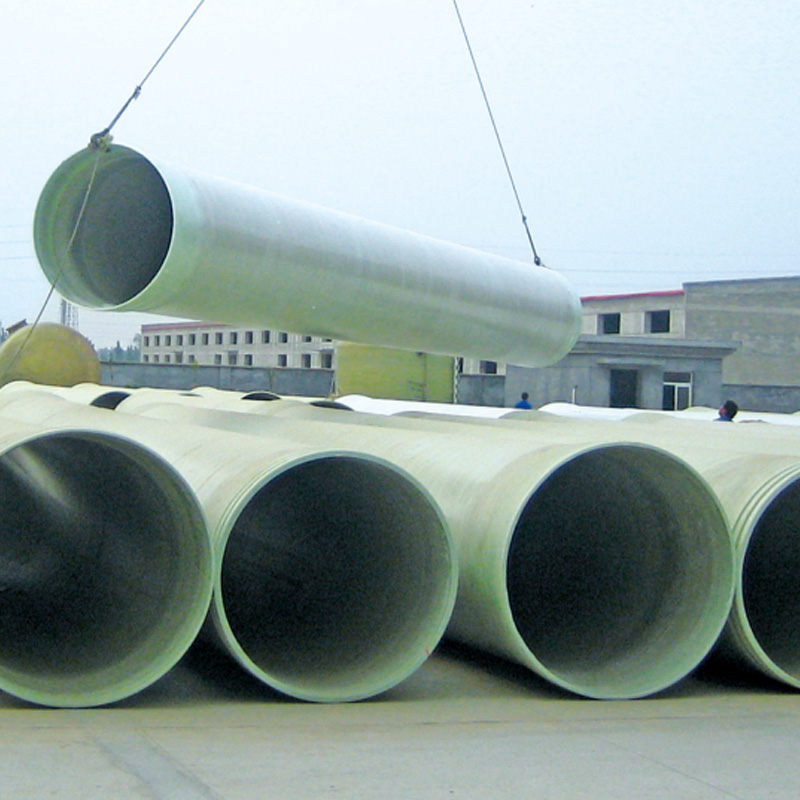

FRP-Sandwich Pipe

Category:

FRP pipe

Tel:

E-mail:

Details Introduction

The sand-core FRP pipe is manufactured using a specialized process with resin (food-grade resin for potable water applications), fiberglass reinforcement, and quartz sand as raw materials.

Suitable Fields

1. Potable water transportation;

2. Sewage discharge;

3. Seawater transportation;

4. Power plant circulating water pipelines;

5. Transportation of corrosive media in chemical plants:

6. Oil and gas transportation;

7. Agricultural irrigation.

Advantages of FRP Sand-Core Pipes

1. Excellent Corrosion Resistance & Water Safety

FRP pipes resist acids, alkalis, salts, seawater, untreated sewage, corrosive soils/groundwater, and various chemical fluids without affecting water quality.

2. Anti-Fouling & Microorganism Resistance

The smooth, non-reactive surface of unsaturated polyester resin prevents fouling by marine organisms (e.g., barnacles) and microbial growth.

3. Thermal Stability (-50°C to 110°C)

-

Maintains strength and toughness at -30°C

-

Long-term service range: -50°C to 80°C

-

Special resin formulations allow operation above 110°C

4. Lightweight & High Strength for Easy Installation

-

Density: 1.65–2.0 g/cm³ (1/4 the weight of steel)

-

Tensile strength:

-

Hoop: 180–300 MPa

-

Axial: 60–150 MPa

-

-

Bell-and-spigot joints enable rapid installation

5. Low Friction Loss & High Flow Efficiency

-

Ultra-smooth interior (Hazen-Williams coefficient n=0.0084) vs:

-

Concrete pipe (n=0.014)

-

Cast iron (n=0.013)

-

-

Reduces head loss by 20–40% compared to traditional materials

6. Electrical & Thermal Insulation

-

Volume resistivity: 10¹²–10¹⁵ Ω·cm

-

Thermal conductivity: 0.23 W/(m·K) (0.5% of steel)

7. Abrasion Resistance & Low Maintenance

-

No need for:

-

Cathodic protection (saves >70% maintenance costs)

-

Anti-corrosion coatings

-

Insulation upkeep

-

8. Customizable Design Flexibility

Tailored pressure ratings (up to 6.4 MPa) and stiffness classes (SN2500–SN10000) for project-specific requirements.

9. 50+ Year Service Life (Verified)

Accelerated aging tests confirm >50-year lifespan in buried conditions.

10. Superior Life-Cycle Economics

-

Lower total cost for large diameters (economies of scale)

-

Zero routine maintenance for underground installations

Cases

|

|

|

| Olympic water transportation project construction site |

DN1400 fiberglass reinforced plastic pipes with sand filling,manufactured and supplied for the 2008 Beijing Olympic Games infrastructure project, used in the Beijing Shunyi water diversion project |

Sand-filled pipes manufactured by our company in 2009 for the Dehui branch line project of the Songshu water supply project in central Jilin Province |

Wall Thickness Parameter Table of Sand-filled Pipes

| Stiffness | SN2500 | SN5000 | SN10000 | |||||||

| Pressure | MPa | MPa | MPa | |||||||

| Diameter | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 1.6 |

| 300 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | |||||

| 350 | 8.2 | 7.6 | 8.2 | 8.2 | 7.6 | |||||

| 400 | 8.2 | 7.6 | 8.5 | 8.2 | 7.6 | |||||

| 500 | 7.1 | 7.2 | 7.0 | 8.8 | 9.0 | 8.6 | 11.1 | 11.3 | 10.6 | 9.2 |

| 600 | 8.4 | 8.6 | 8.3 | 10.5 | 10.8 | 10.0 | 13..4 | 13.4 | 12.4 | 11.9 |

| 700 | 9.4 | 9.6 | 8.3 | 12.3 | 11.9 | 11.5 | 15.5 | 15.1 | 14.2 | 13.4 |

| 800 | 11.2 | 10.7 | 9.8 | 14.0 | 13.3 | 12.9 | 17.8 | 16.8 | 16.1 | 14.9 |

| 900 | 12.5 | 11.9 | 10.8 | 15.8 | 15.5 | 14.2 | 20.0 | 19.0 | 17.8 | 16.7 |

| 1000 | 13.9 | 13.2 | 12.3 | 17.5 | 16.6 | 15.8 | 22.2 | 21.0 | 19.7 | 18.2 |

| 1100 | 15.4 | 14.5 | 13.6 | 19.3 | 18.3 | 17.2 | 24.6 | 23.4 | 21.7 | 20.8 |

| 1200 | 16.0 | 15.5 | 14.5 | 21.0 | 18.4 | 18.6 | 26.8 | 25.0 | 23.3 | 21.8 |

| 1300 | 18.1 | 16.7 | 15.6 | 22.9 | 21.5 | 20.0 | 29.2 | 26.9 | 25.5 | 23.6 |

| 1400 | 19.5 | 17.7 | 16.4 | 24.6 | 22.4 | 21.5 | 31.2 | 28.6 | 27.0 | 25.5 |

| 1500 | 20.7 | 19.0 | 17.7 | 26.1 | 24.4 | 23.5 | 33.2 | 30.4 | 29.6 | 27.1 |

| 1600 | 21.8 | 20.5 | 19.2 | 27.8 | 26.0 | 24.5 | 35.4 | 33.3 | 31.0 | 28.9 |

| 1800 | 24.6 | 22.6 | 20.4 | 31.3 | 28.8 | 26.8 | 39.9 | 36.9 | 34.1 | 31.3 |

| 2000 | 27.4 | 25.4 | 23.4 | 35.0 | 32.4 | 29.6 | 44.7 | 38.2 | 37.3 | 36.1 |

| 2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 42.5 | 41.5 | 40.4 |

| 2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 45.8 | 44.6 | 42.8 |

| 2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 48.9 | 47.2 | 45.6 |

| 2800 | 39.3 | 36.0 | 34.0 | 49.4 | 45.1 | 42.0 | 62.0 | 56.5 | 53.0 | 51.0 |

| 3000 | 41.0 | 38.1 | 36.2 | 52.0 | 47.0 | 45.3 | 67.0 | 61.7 | 58.2 | 54.0 |

Key words:

FRP pipe

Previous Page:

Next page: