Products

Contact Us

Telephone:

086 318-8613433 086 318-8638136

Mobile:

+86 13931832669 +86 13932879971

Address:

No.955 Xinghua South Street, Jizhou District, Hengshui City, Hebei Province,China

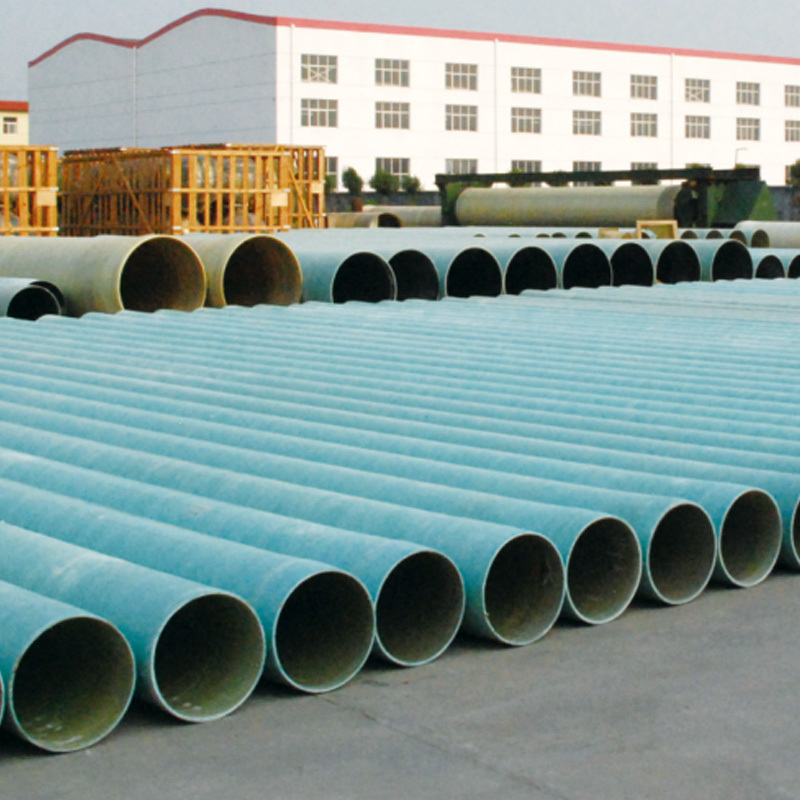

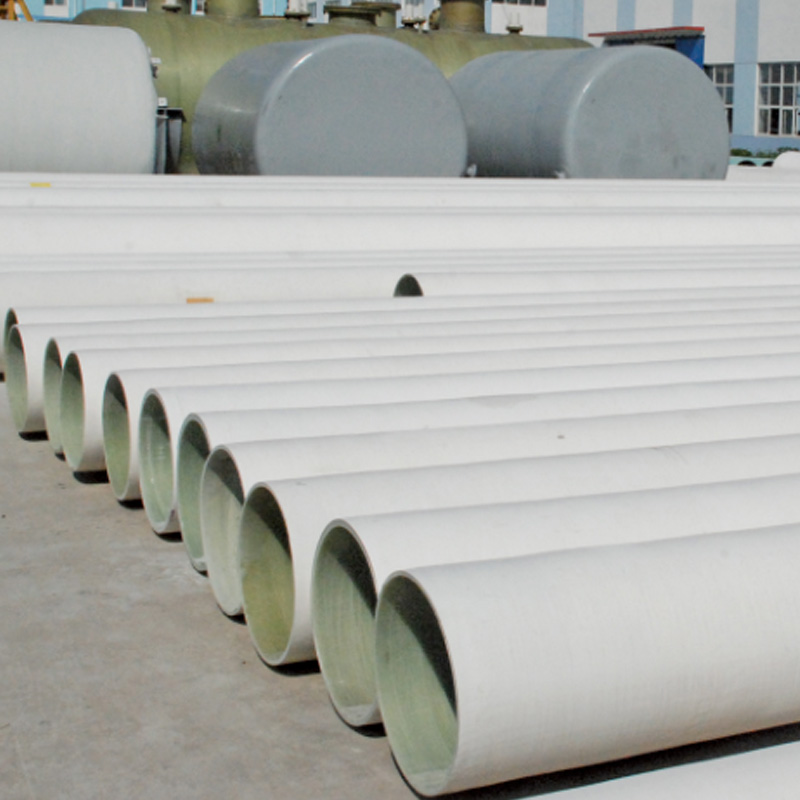

FRP Process Pipe

Category:

FRP pipe

Tel:

E-mail:

Details Introduction

Advantages of the FRP pipe

1. Corrosion resistance: select different types of anti-corrosion lining resin, used in different environment of acid, alkali, salt, and various oils, sea water and organic solvents.

2. Light weight, easy maintenance, durability.

3. Easy to install: FRP pipe length has no technical limitations, but in consideration of the transport, pipe length is generally less than 12m, so that greatly reduce the quantity of joints, due to the light weight of FRP, pipe can also be installed by hand or light installation equipment, easy and quick.

4. Good applicability: existing standard diameter of FRP pipe is between 25mm-4000mm, long-term pressure bearing ability is generally less than 1.6Mpa, in accordance with the special needs of the users, the higher pressure of 6.4Mpa is achievable.

5. High transmission capacity: pipe wall is smooth N-≤ 0.0084. Compare with traditional pipe which has same diameter, it has a higher flow capacity, so it can save pump energy and extend project life.

6. Low permeability: because of the good sealed connection and the longer length of each pipe, FRP pipe has a lower permeability than traditional pipe, thus greatly reducing the risk of both groundwater penetrate into pipe and media penetrate out and contamination environment.

7. Rigorous test standards: our company has advanced testing equipments, and strictly implements inspection standards to ensure product quality. The relevant standards: ASTM, AWWA, ASME, etc.

8. Low cost and long life cycle: FRP products which have a long service life, basically not need maintenance, installation and transportation costs is very low.

FRP Process Pipe

FRP process pipe which is characterized by performance in the n ≤ 0.0084, has a very smooth wall, so that the fluid transport pressure loss is very low, therefore, compare with traditional pipe, we can choose smaller diameter pipe or lower power pump to transmit same flow. For long distance transmission, large diameter pipe can also reduce the cost of installation, insulation, anti-corrosion and maintenance; this is the reason FRP process pipe has a good reputation of energy saving.

Characteristics

1. Cold resistance: in a frozen medium, pipe will not be cracking. lowest temperature is -50℃;

2. Heat resistance: highest temperature is 250℃;

3. Corrosion resistance: client can choose different corrosion-resistant pipe for different media;

4. Pressure: design and fabricate the pipe depend on process required pressure, the liquid filling test pressure is 1.5 times of design pressure;

5. Good insulation: after development, it can eliminate static electricity;

6. Good flame resistance: after development, it can be self-extinguishing, inflaming retarding and flame repellent;

7. Perfect transparent performance: after development, it can be colorful;

8. Good heat insulation: after development, thermal conductivity can be improved;

9. Non-toxic: it can be used for transmitting drinking water

FRP process pipelines enjoy a significant reputation for energy saving, mainly because n≤0.0084. Due to their smooth inner walls, they have low fluid transport pressure loss. Therefore, for the same flow rate, smaller diameter pipes or lower-power transfer pumps can be used for long-distance transportation. Large-diameter pipelines can also reduce installation costs, insulation costs, eliminate anti-corrosion costs, and avoid major repair expenses.

Process Pipeline Characteristics

• Cold resistance: The pipeline will not be frozen and cracked under freezing medium.

• Corrosion resistance: In an intricate and crisscrossing environment, different corrosion-resistant pipelines can be selected according to the requirements of the medium.

• Pressure resistance: Design and manufacture pipelines and pipe fittings according to the required process pressure, and perform pressure tests at 1.5 times the process pressure;

• Heat resistance: The low-temperature resistance is -50℃, and the high-temperature resistance is 250℃.

• Good insulation performance, improved to eliminate static electricity.

• Good flame retardancy, improved to be self-extinguishing, flame-retardant, and fire-resistant.

• Good transparency, improved to be colorful, good insulation performance, improved to enhance thermal conductivity.

• Non-toxic: Can be used for drinking water transportation.

|

|

| Fiberglass reinforced plastic (FRP) pipes manufactured and supplied for the Keppel Group in Singapore, Used in China's largest seawater desalination plant - Tianjin Dagang Xinquan Seawater Desalination Plant. |

Fiberglass reinforced plastic (FRP) pipes and fittings manufactured and supplied for IDE Technologies Ltd, Used in Tianjin Beijiang Power Plant, one of the earliest large-scale seawater desalination plants in China. desalination plant (100000m2freshwater/day) |

Project Name: DN1800 Reinforced Pipe

Client: Singapore

|

|

Key words:

FRP pipe

LTD.

Previous Page:

Next page: